Roam's Glow Up

A well deserved refit in New Zealand

Entropy is the tendency of a system to move from order to disorder. It applies to sailboats as well as physics. It’s why boats are in a constant state of deterioration.

After three years and 10,000 nautical miles, it’s time to reverse the entropy. Roam is out of the water, on the hard, and in the paint shed getting a well-deserved sprucing up. She is 25 years old. Some of the systems, components, and furniture are original. Sailors call this a “refit.”

New Zealand is a great place to get boatwork done. You meet people here who describe themselves as “boat builders.” That title is on their business card. There is a vibrant boat-building scene in New Zealand. With the NZ dollar at its present level, project costs are two-thirds of the US for the same work (assuming you could even find someone to do the work).

Greg Prescott runs Tauranga Marina and boatyard. He’s a fellow Catana owner. We got connected a few years ago via the Catana Owners Group. He made a persuasive case to bring Roam to Tauranga if we ever got the chance. He knows how to haul and block these boats. He was willing to project manage the work while we were away. He did to his boat many of the projects we’re doing to ours. The value of an experienced project manager cannot be overstated.

Most of the boat work is headed up by Tim Marra and his team at Marra Marine. Jessie from Passion Painters is handling the gelcoat and paint work.

The yard figured out a way to back us into the paint shed up to the mast. That allowed them to seal off the cockpit area being prepped and painted without us having to pull the mast out of the boat. Painting the cockpit inside the shed keeps the paint out of the air and the overspray off the neighboring boats.

We head back to New Zealand in a few weeks. The process of putting the boat back together starts then. So far, work has proceeded at a brisk pace. We’re excited to see our girl!

A Few Photos

Cockpit Refresh

Sailing the tropics is an exercise in outdoor living. Our cockpit is our patio during the the time we are anchored (99% of the time). Over the years, it became festooned with old instruments, cables, snaps, screens, and other random fittings. These things and the holes they created spread like a pox. We are removing them, filling the holes, and painting the cockpit.

We’re also having a new enclosure made for the cockpit. The enclosure keeps the sun, rain, and sea spray out of our living area. It needs to stay out of the way while sailing. And, it needs to stow away when the weather is nice. Think of it like a screened-in porch. Matt and the team from Fabric Solutions are on the job.

Galley

Pam is upgrading her kitchen. She’s been cooking with a portable induction hob and a Breville convection oven (along with an Instapot, a microwave, and an electric kettle). We never use the original propane stove. It’s been lit it once—when testing it during the purchase survey. Cooking is so much faster and easier with induction. It doesn’t heat up the cabin like propane does. And we don’t have to spend time chasing down a source to fill our propane tanks in far-away places.

She is looking forward to a proper built-in induction stove. The OceanChef 3 is a work of art! This will free up counter space where the convection oven currently lives. These are made in the UK. We had it shipped and imported into NZ.

Saloon

Think back to 2001. What was the dominant format for video and music? Yes, DVDs and CDs. And those amazing craftsmen at Catana built beautiful cabinets to hold all of that. Today, those cabinets are worthless. They take up a ton of space and can’t store anything. Out they go.

The team will refinish the shelf with a laminate that matches the walls. This will create a TON of new space for things we need every day. This has been bugging me for years.

Deck Hatches

Hatches on the deck are a mixed bag. They can let in air and light at anchor. They also let in rain and seawater. Roam’s designer was not a big fan of them, and you’ll find very few deck hatches in his designs. We have four—two in each bow and two in each transom step. The bow hatches provide access to the bow lockers where we store sails, lines, and toys. The hatches in the sterns provide access to the engine rooms.

Over time, the frames leak. Water gets into the below-deck spaces. The deck coring can get saturated as well. That’s what happened in our case. Think of the deck as a peanut butter sandwich. The fiberglass outer skins are the bread. The inner core is the peanut butter. The core is made from foam, balsa wood, or plywood, depending on the location and loads. Tim’s team dug out the old, rotten core and grafted in new foam. Good for another 25 years!

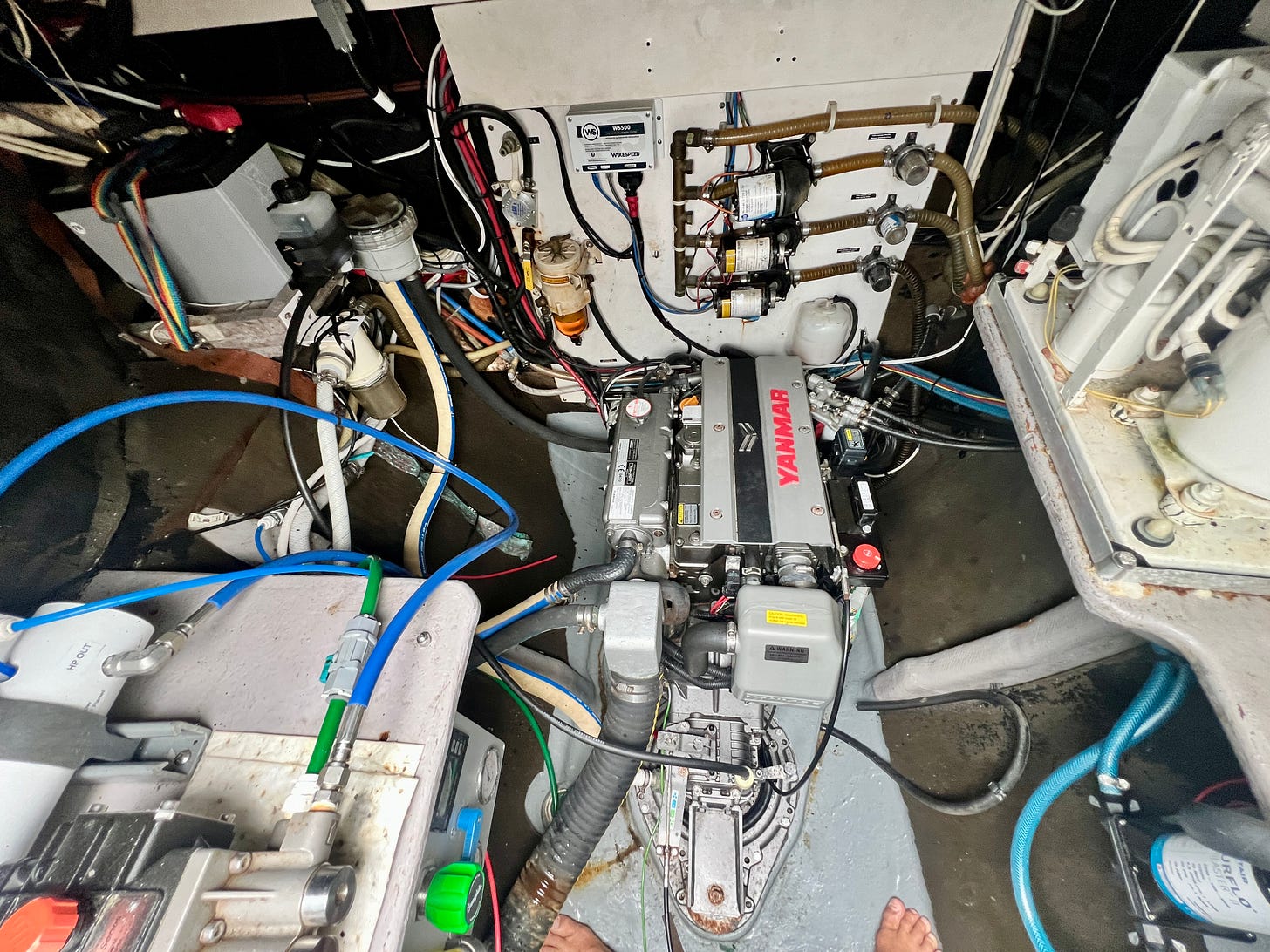

Engines

The engines and generator need regular service. Like your car. Oil and filter changes. Transmissioin fluid in the saildrives. Fuel filters. Seawater cooling pumps.

Our engines are new. They were due for their 1,000-hour service (well-maintained, they can last for 20,000 hours). Part of that service involves adjusting the valve clearances as well as examining the codes put out by the engine’s computer. I don’t mind doing routine oil changes, but we decided to leave the other stuff to the professional engine techs. Both engines and the generator got a clean bill of health from Marine Diesel Service.

We’ll also wire the engine control units into the boat’s network so that the engine parameters will display on our sailing instruments and chart plotters.

Toilets

We’ve managed to keep our complicated VacuFlush toilets running. They take a lot of attention. They are complicated and they are loud. They sound like the toilet in a commercial aircraft. They rely on a vacuum generator under the floor. This effectively creates a second holding tank in each hull. The fewer holding tanks in life, the better.

One evening we were aboard our friends Mary and Kevin’s boat, Pisces. Pam emerged from below having used their head. She looked at me, pointed her finger, and said, “We are getting one of those.” Happy wife, happy life. The old VacuFlush system will come out, and their place will go new Sanamarin 31 toilets. These are simpler and more reliable. Trust me, this is a good thing.

Sails & Rigging

Sam Burton of Burton Sails has inspected and repaired our working sails. He’s been great to work with. Full of excellent advice.

He has also modified our “stack pack”—the sail bag that holds the mainsail when it is furled. I’ve had a difficult relationship with that damn thing. I can never get it zipped up. He has that solved.

Our sails are under-spec’d for the boat. Okay for tooling around coastal Mexico but not built for the kind of full-time ocean cruising we are doing. We should be able to get another season or two out of them. But their days are numbered. Replacing them is a big project and not cheap.

His neighbor, Scott, runs McCormick Rigging. Scott is going to inspect everything and replace a few halyards. He’s made some recommendations for us to implement when we go to replace the sails. Mainly, removing the forward permanent Harken furler and replacing it with a removable structural furler. A project for next year, I think.

Rudders

Rudders are a failure point in offshore boats. On some boats, loss of the rudder is catastrophic and can sink the boat. Fortunately, catamarans have two of them. They are usually designed in such a way that the loss of the rudder doesn’t jeopardize the integrity of the hull. We have friends who’ve made passages with only one rudder. One arrived at the end of a passage only to discover they were missing a rudder but never realized it. And, a captain we met last year lost BOTH rudders and still managed to go 700 miles to Fiji using only a Jordan Series Drogue for steering.

The bearings that hold them wear out. We had new ones made locally. Dropping the rudders allows us to inspect them and replace the bearings. JP3 Steering Systems makes our rudder bearings from “Ertalyte”. It’s a good choice. But a local manufacturer has a better version of it with improved self-lubricating properties. We’ll try it. Our project manager, Greg, figured this out and had them made.

Anchor

Our steel Rocna Vulcan anchor is galvanized to protect the metal and prevent corrosion. The anchor takes a beating. The galvanizing gets compromised. Greg had it sandblasted and re-galvanized using Rocna’s recommended process. Sailors develop a close relationship with their anchors. Have I mentioned how much I love this anchor?

The Complete NZ Refit Project List:

Hull and Deck

Replace all below-the-waterline bronze thru-hull fittings with New Zealand-made TrueDesign thru-hulls (Kiwis call them “skin fittings”).

Reseal the hull-deck joint.

Fill and fair minor chips and nicks in hull gelcoat.

Polish and wax the hull and topsides.

Repaint the antifouling paint on the bottom.

Replace the bootstripes and hull graphics.

Replace the rudder bearings.

Touch-up paint on the dinghy davits and crossbeam.

Replace the mid-deck locker latches.

Recore bow locker hatches.

Recore engine room hatches.

Install composite hanging rods inside the bow lockers.

Replace port engine exhaust fitting (I broke that while docking in Fiji).

Repair and repaint the line tunnel end cap fitting.

Reseal longeron joint.

Repair linewell drains.

Remove old wind generator pole fittings and fill holes.

Cockpit

Remove old instruments and fill mounting holes.

Remove and fill all old, unused snaps and fittings.

Re-route solar panel wiring in hidden conduits.

Repaint cockpit bulkheads, seats, transom steps, and Bimini supports.

New cockpit enclosure and sun shades.

Replace table base. Fix table so it will fold up and refinish.

Refinish steering wheel spokes.

Refinish varnish trim.

Interior

Remove home theater boxes from saloon settee shelf.

Recover saloon wall panels.

Recover saloon shelf with laminate.

Replace propane stove with OceanChef induction stove.

Recover ceiling panels in all staterooms.

Replace Vacuflush toilets with Sanamarin 31 toilets.

Replace the mattresses in our master stateroom.

Repair the delaminated stair steps.

Engines & Generator

1,000-hour engine service on the Yanmar 4JH57 engines.

200-hour service on the Northern Lights generator.

Remove Algae-X units from fuel lines.

Rebuild generator seawater pump.

Rebuild starboard engine seawater pump.

Sails & Rigging

Inspect the rigging.

Replace the main halyard.

Replace the topping lift.

Repair the main, Solent, and Code65 sails.

Repair and modify the stack pack.

Ground Tackle

Replace our damaged primary anchor chain (under warranty).

Regalvanize our Rocna Vulcan anchor.

Replace the 3-strand nylon backup anchor ropes with octaplait.

Replace the primary anchor shackle.

Electrical

Replace bow navigation light

Rewire generator output directly into Victron Quattro Inverter

Integrate Yanmar engine ECUs into NMEA2000 network

Dinghy

Outboard motor service